Passenger Trains

On-board inspection technology

The installation of vision sensors on-board a passenger train is a considerably challenging task. Passenger trains are designed to carry passengers, not host big and bulky inspection equipment. Over the last decade it is becoming imperative that measurement equipment are designed to be mounted on such vehicles in order to reduce costs, remove maintenance vehicles from the track that take up capacity, move to remote operations, and perform more regular inspections than possible with limited number of inspection vehicles. Obviously on the flip side the challenge is that if the equipment is not portable, adequate number of locomotives will need to be equipped that can cover the entire network between them.

The design of vision equipment for mounting on passenger trains is significantly more challenging that mounting on maintenance vehicles. The following Table shows the design requirements that are important.

| Passenger vehicles installation requirements | |

|---|---|

| Limited space | Underframe space is highly limited. The design needs to be compact to fit under the vehicle. |

| Limited power | Passenger trains have limited power to provide so most designs requiring beyond 5KW will be difficult to accommodate. It is not easily possible to put separate generator and ideally all AC/DC power should be taken from the train. |

| Unattended operation | Passenger train drivers cannot operate the system. For regular inspections, unattended and remote operations are preferred. |

| No in-cabin equipment | Passenger vehicles may not have any space inside passenger coaches to put any equipment components. Designs need to consider complete out of cabin mounting. |

| In-field maintenance not possible | Passenger trains may not be in maintenance workshops for long periods so efficient maintenance planning is needed. These trains cannot be stopped for equipment maintenance in the field. |

| Neural sections | Passenger trains often go in neutral sections that cuts off power. DC power management to keep system working is important. |

| Mechanical constraints | The physical mounting of equipment on trains is more challenging than maintenance vehicles as welding, drilling and other operations may not be allowed as freely. |

TrackVue installation

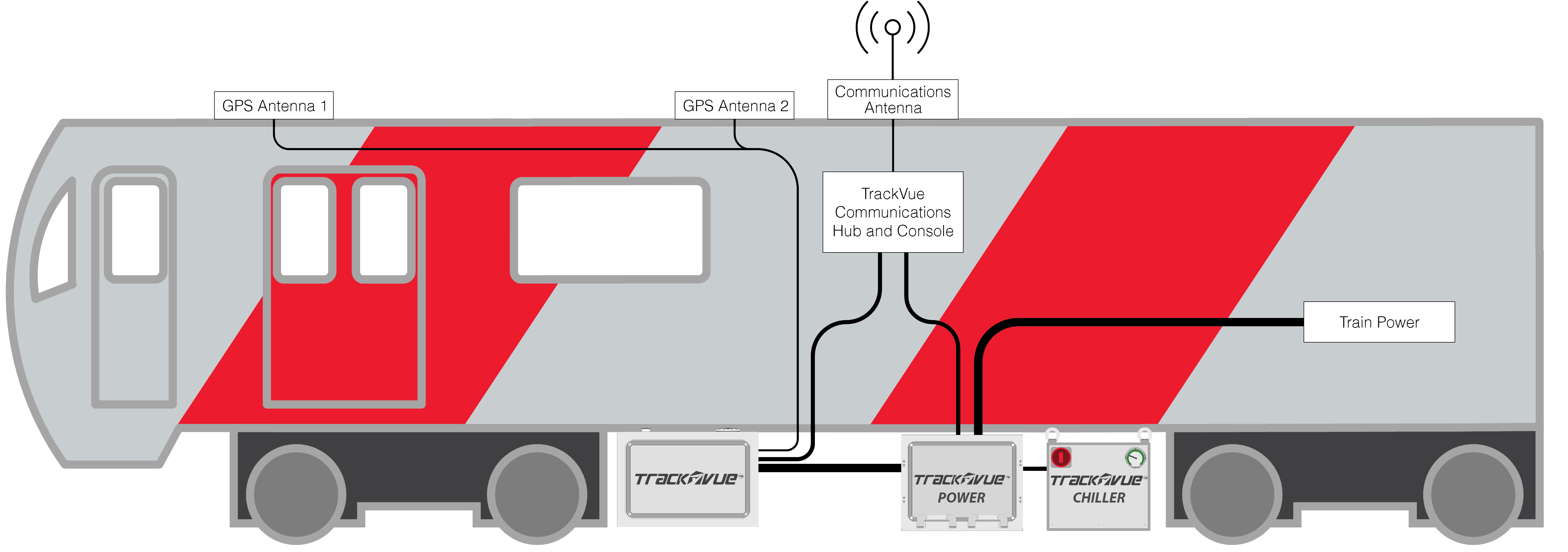

Rail Vision’s TrackVue Z series, S series and V series are physically mounted on the train without using any in-cabin space and are fully compliant with the requirements set-out in the above table, in addition to working within the maximum allowed kinetic dimension of the vehicle. The following picture shows the mounting arrangements on a passenger vehicle where the equipment is liquid cooled with an external chiller. For models with convection cooling, this component may be dropped.

In the above picture, all equipment sits outside of the train. GPS and data communication antennas are installed on the roof top for a clear view of the sky. Train power is converted to 24VDC suitable for our equipment. The following short video shows our equipment once installed on a passenger train.