Accidents & Derailments

Background

Train accidents and derailments are often a result of track or wheel damage in addition to either human mistakes or result of system failures (e.g. signalling). Keeping rail tracks and trains in good condition and performing adequate maintenance regularly is very important for maintaining rail safety. Accidents and derailments lead to loss of life, damage to track and trains that are costly to repair, loss of customer confidence and loss of revenue until normal operations resume. These costs may be compounded by any penalties imposed by rail regulators and litigation and compensation claims.

Regular track and train monitoring for predictive maintenance is very important. Detecting issues at an early stage allows repairs to take place at a lower cost and with less effort rather than leaving these for later. Rail Vision systems are aimed at providing a comprehensive tool set for operators to provide regular track diagnostics and use this data as a maintenance tool.

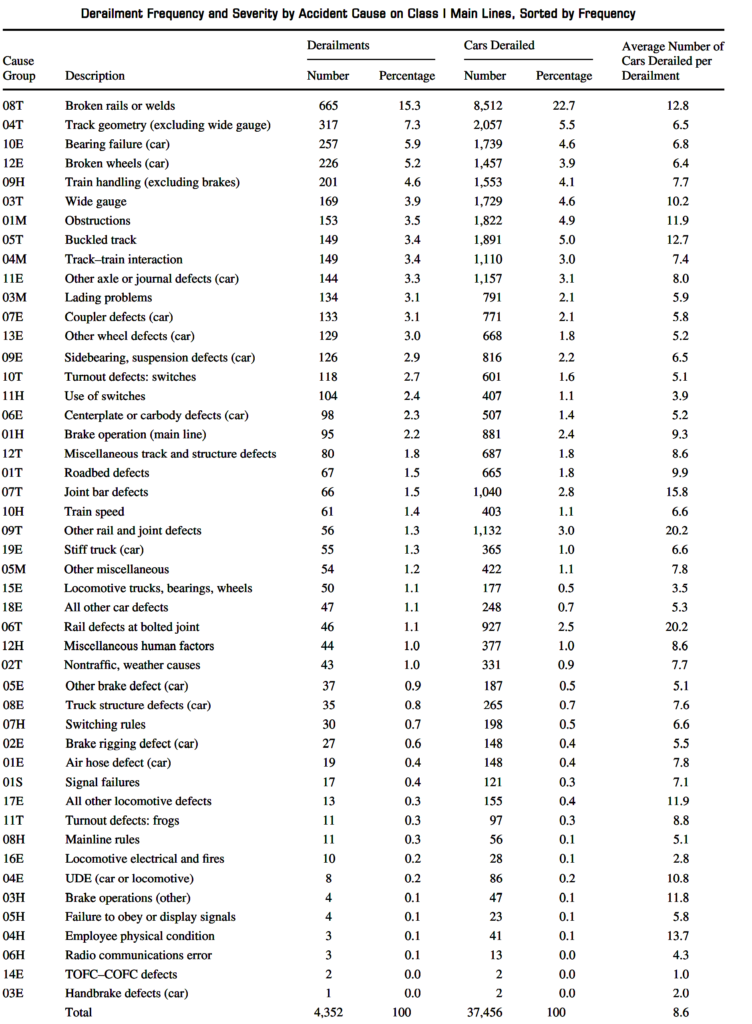

The following Table published by researchers at UIUC, USA shows data from class 1 railroads which spells out the main reasons behind train accidents. Rail Vision equipment is used detect

Accidents caused by top 5 reasons shown below can be reduced through Rail Vision equipment inspections. These include

- Broken rails of Welds (responsible for 15.3% of all accidents)

TrackVue Z series uses linescan imaging technology to detect broken rails and welds

- Track geometry (excluding wide gauge) (responsible for 7.3% of all accidents)

TrackVue Z series uses laser and inertial sensor data to measure track geometry

- Bearing failure (car) (responsible for 5.3% of all accidents)

TrackVue R series on-board condition monitoring equipment detects bearing failures

- Broken wheels (responsible for 5.3% of all accidents)

TrackVue R series undercarriage monitoring and wheel measurement system coupled with linescan imaging can detect broken wheels

- Wide Gauge (responsible for 3.9% of all accidents)

TrackVue Z series detects wide gauge defects

RV Diagnostics

Rail Vision is not only a supplier of track monitoring devices. We work together with customers to provide AI based data analytics during post-processing and provide further multi-sensor data fusion tools to perform a robust set of information on track and train condition. Our solutions can be used at high speeds and on a wide variety of platforms including passenger trains that ensures that regular diagnostic data is collected and used for maintenance. Reducing risk of accidents and derailments is one of our core services to railways.