Estimating Root Cause of Failures

Measurements – what do they tell?

Sensor measurements provide specific information about the object of interest. These may measure surface properties, sub-surface properties, temperature, vibration or acoustics. As a first step, all measurements can be simply thresholded to seek abnormal deviations and flagged for expert opinion on what to do next. As a second step, changes in measurements may show the condition of assets changing over time. In both cases, we do not fully understand the reasons behind deteriorating assets. A low rate of degradation may be attributed to general wear and tear, however, a rapid deterioration in condition may raise huge concerns as the cost of repairs and renewals will be very high. For most railways, identifying the root cause of problems that lead to rapid decay in the condition of components, e.g. rails, sleepers, wheels, bearings, pantograph carbon strips and so on, can be very difficult.

Understanding the root cause of problems is a different science to predicting maintenance requirements in the future. It is about preventing the need for excessive maintenance by understanding what is causing rapid deterioration of assets. Such a science requires a combination of expert railway knowledge, understanding of railway maintenance practices (e.g. rail grinding, tamping etc.), a thorough understanding of what sensors are telling us individually and collectively, and a background in advanced data analytics to correlate data from sensors, maintenance works, engineers, track designs, rail wheel interaction, etc. Only then a root cause may be hypothesised. Once we have a hypothesis, we can plan an action to try out an approach on limited track segment to fix the issue and see if it makes a difference. Consequent fixes are experimental but based on science as opposed to random actions that do not fix the issues.

RV Approach

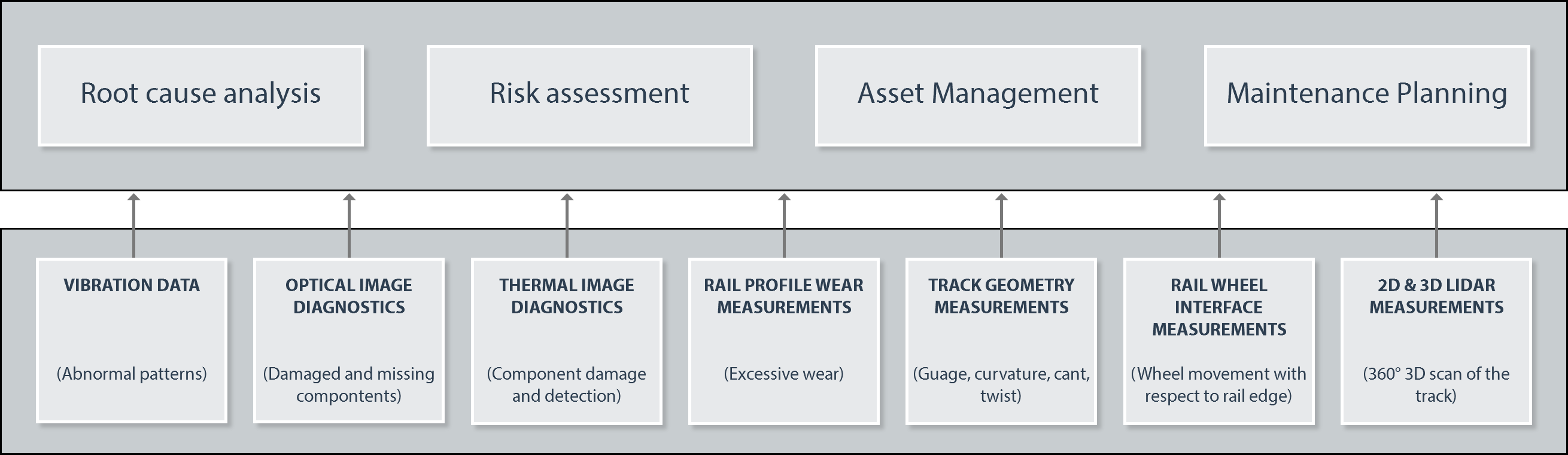

Sensor data forms the basis of a detailed understanding of root cause behind most problems. The following figure shows the input and output layers of decision making. Sensor data from multiple sources is used as input and fed into a Middle Layer, which generates Artificial Intelligence processed output to serve four main functions: Root cause analysis, Risk assessment, Asset management and Maintenance planning. Root cause analysis involves both sensor processed information that can be used for decision making and human expertise that additionally considers data from other sources (e.g. past maintenance activities).

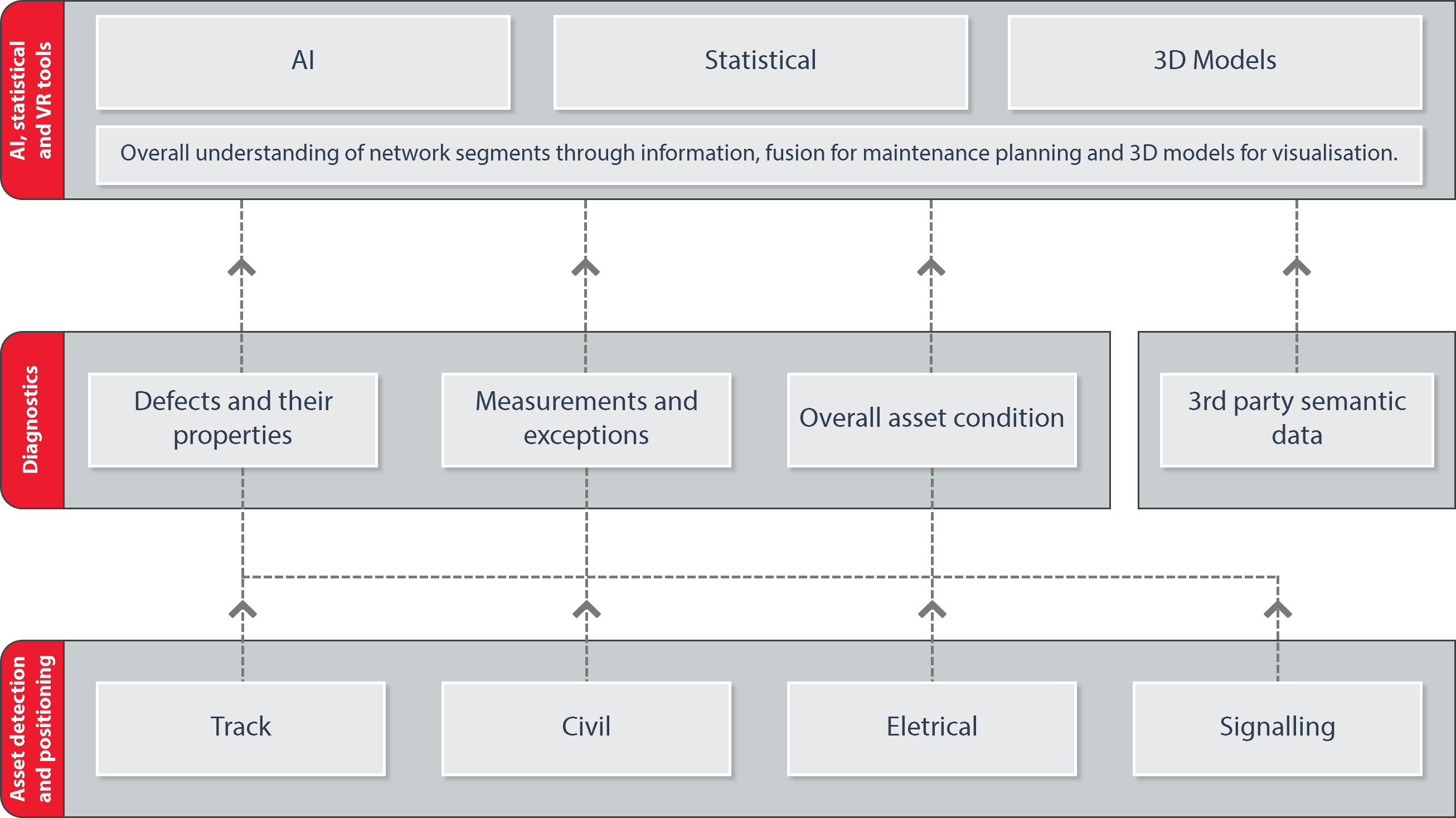

The Middle Layer is what transforms the raw sensor data into useful information used for Root Cause Analysis. The contents of this layer are shown below. The assets under inspection may come from track, civil structures, electrical structures and signalling components. Sensor data needs to be translated into measuring asset condition and changes in asset condition. Third party data, e.g. grinding, tamping, past renewals, track geometry designs, ground penetrating radar information, etc. is very important in establishing the actual track condition. A range of AI and statistical tools (e.g. deep learning, neural networks, fuzzy logic, genetic algorithms, probabilistic models) can be applied to understand relationships and establish cause and effect.