Sleeper Diagnostics

Background

The stability of sleepers is critical for holding the rails and associated fastening for both concrete and wood. Excessive stress on the sleepers may cause them to fracture, break, or move. The accurate identification of sleepers and assessment of their condition, measurement of their interspacing, positioning both in two and three dimensions for skew and vertical displacement, and identification of defects on them (cracks, breaks, wheel damage) and damage to their fastenings/plates form an overall assessment of sleeper quality. Mudslides on sleepers can be further used to detect landslides often in rainy periods.

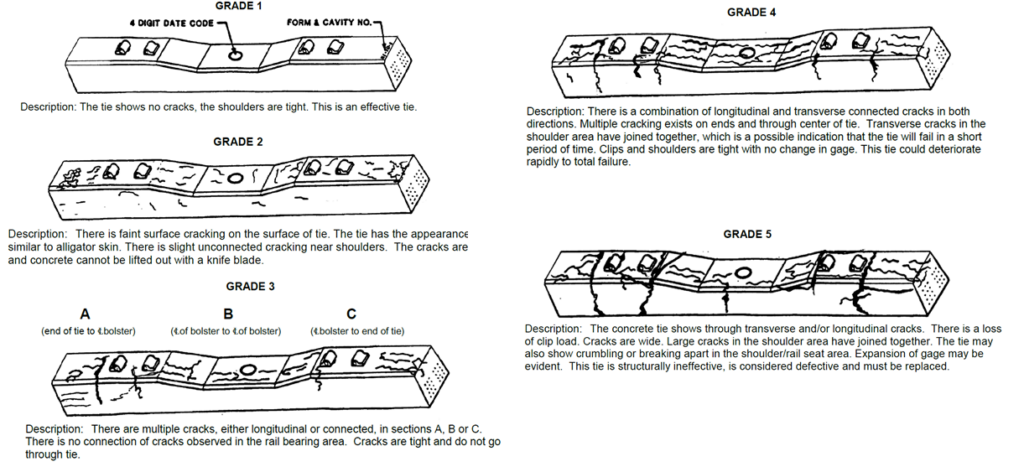

Railroads have adopted standards on grading sleepers, e.g. Grade 1 may be a sleeper with some defects and Grade 5 may be a completely broken sleeper. Diagnostic systems need to grade each sleeper, and then find clusters of sleepers that need replacements or repairs. The following picture shows an example standard for grading concrete sleepers used by both human track inspectors and automated systems.

.

RV Diagnostics

Rail Vision using linescan imaging systems to diagnose sleeper conditions. Each sleeper is graded for condition in a scale of [1…5] as per rules set by Class 1 Railroads in North America. The following table shows the measurements made.

| Sleeper measurements | |

|---|---|

| Type | Concrete, Wood, Slab track, Steel, Composite |

| Cracks and breaks | Length, width, thickness, area, orientation, severity, track position |

| Grade | Grade in a scale of [1...5] based on how human inspectors grade ties using documented standards. Grading takes into account sleeper type, and condition (stability of fastenings, direct damage to sleeper, internal condition (rotten) and its movement (e.g. plate movement). Grade 1: best; Grade 5: worst |

| Orientation | In degrees showing sleeper skew |

| Gap | Inter-sleeper distances between successive pairs in mm |

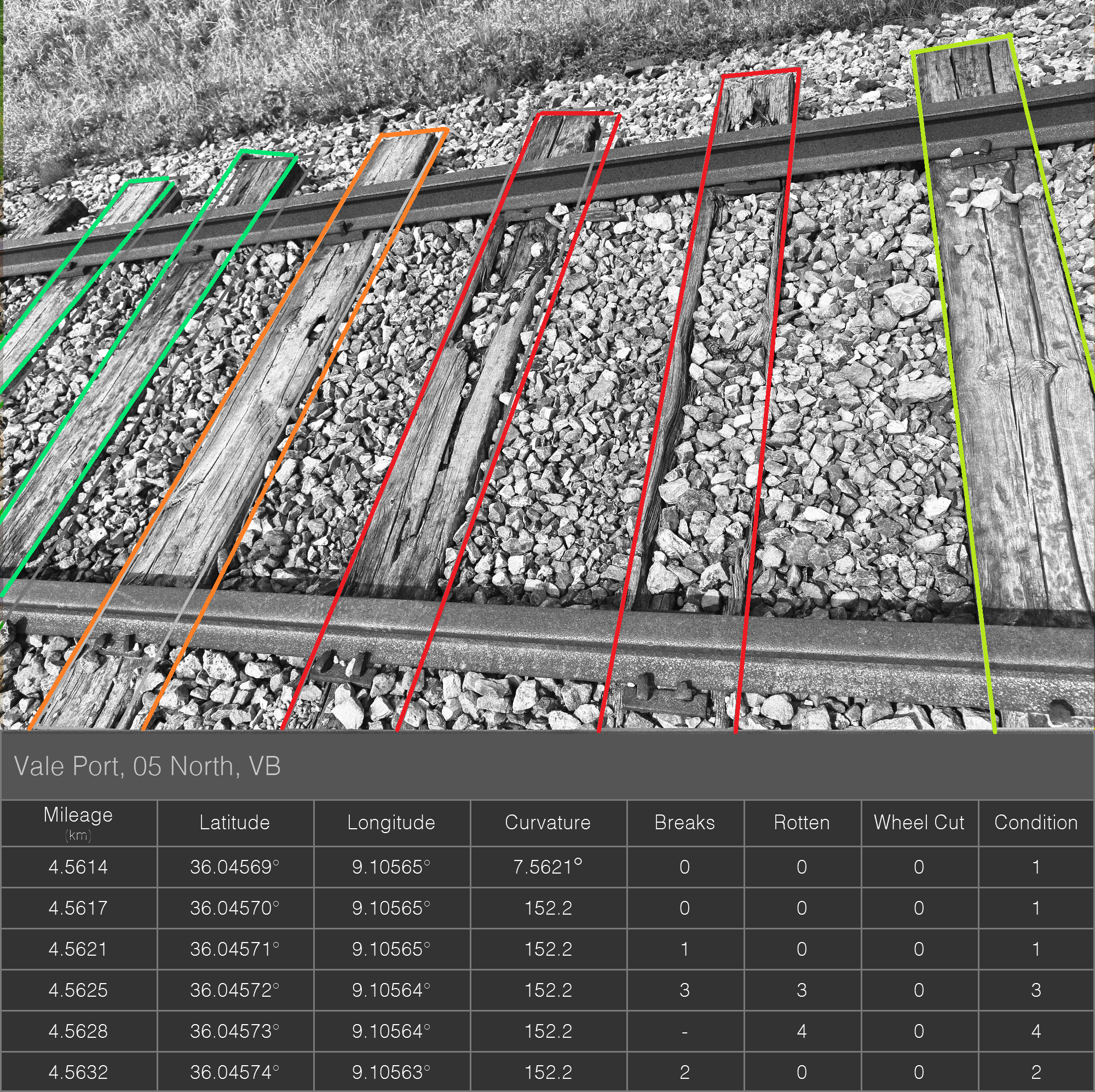

The following image shows the results from TrackVue Z series equipment for grading wood sleepers.

Similarly, concrete sleepers are graded based on the position, thickness and length of their cracks.

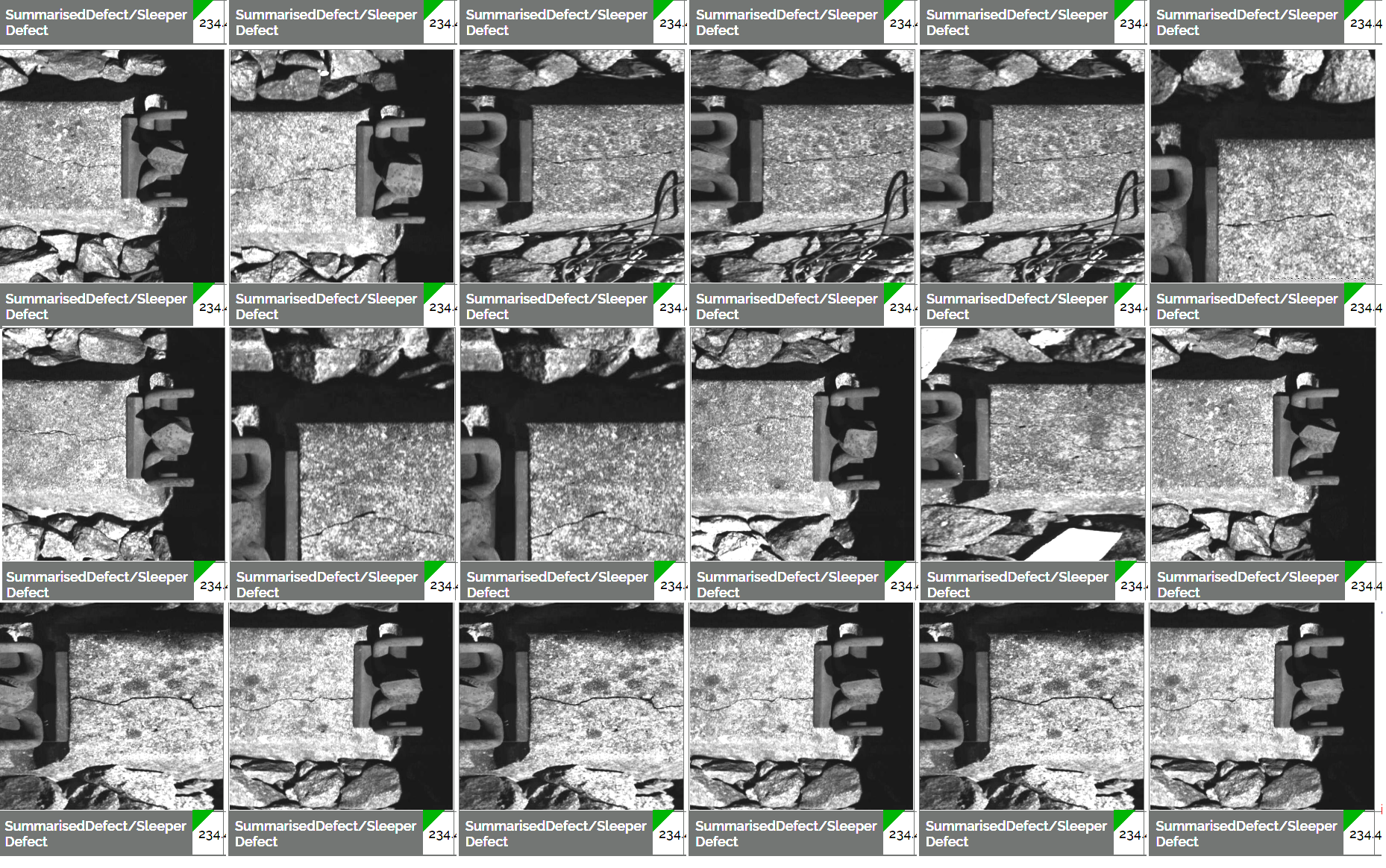

The following slideshow shows concrete sleeper defects identified by TrackVue Z series system.

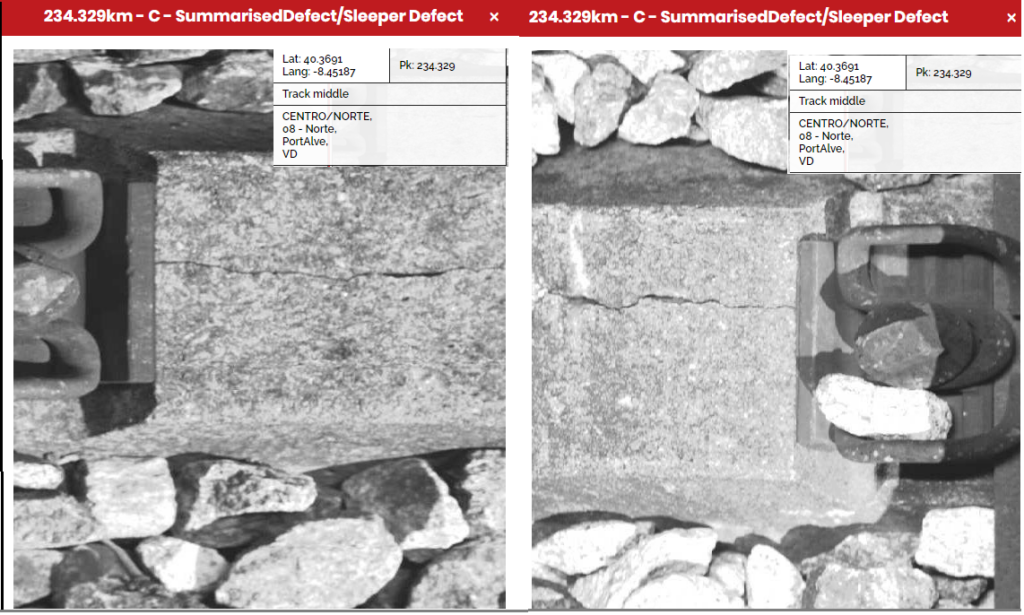

The following images show the defective concrete sleepers with location.

Each sleeper is accurately positioned for track chainage and line details (division, subdivision, segment, track ID) as shown below.

Similarly for wood sleepers, a grading system is adopted for automated labelling each sleeper for condition as shown below.

RV Advantage

The main advantage of using RV diagnostics on sleepers includes:

- Very high resolution image analytics at 0.25mm/pixel for vehicle speeds up to 80 kmph and 0.5mm/pixel for speeds up to 160 kmph allowing us to detect new cracks developing on sleepers.

- An automated grading system for sleepers, compliant with the needs of Class 1 US railroads based on their specifications which are globally acceptable

- Sleeper end-to-end imaging; identification of cracks close to fastenings

- Ability to calculate custom statistics, e.g. number of successive pairs of defective sleepers every 39 feet.