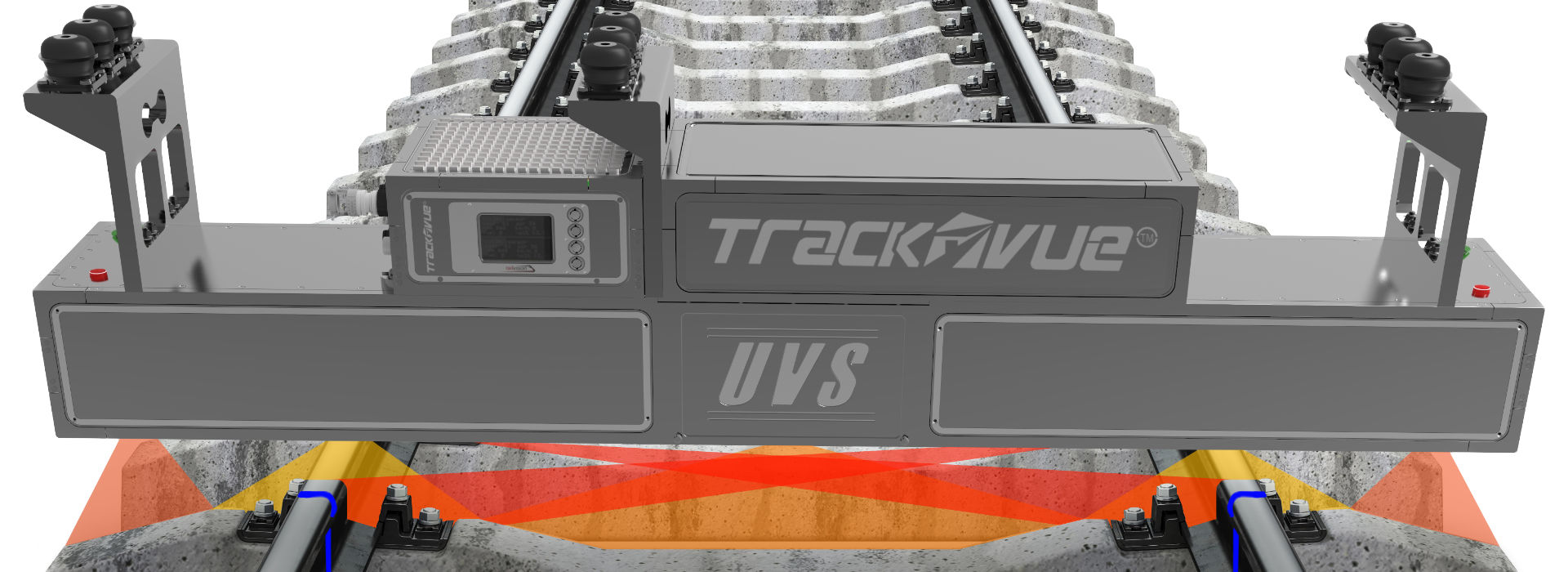

TrackVue Z Series

Integrated Track Measurement Systems

Z series is used for Asset Detection & positioning, asset defect detection, rail profiling, track geometry and rail wheel interface measurements. System outputs include

- Assets positions for switch areas, check rails, level crossings, axle counters, magnets, cables, lubricators, joints, fishplates, welds, etc.

- Rail joint defects including fishplate missing bolts and cracks, excessive rail gaps and damage at joints

- Rail fastenings data & defects including rotated and missing fastenings, baseplate defects, missing anchors spikes

- Rail web defects including weld fractures and rail branding information

- Sleeper classification (wood, concrete, short or full size) and defect data including cracks, breaks, misaligned, rotten, etc with full sleeper grading

- Switch related defects including damage at frog or nose, abnormal rail wear, missing components, running band variation, switch blade distance

- Track geometry measurements including rail type, cant, twist, curvature, gauge, alignments

- Bogie pivot acceleration and vibration measurements

- Rail wheel interface measurements on running surface area, wheel flange and tread contact angles

TrackVue Z series for automated track inspection comes as two models shown above which can be mounted under the train. The first model is liquid cooled and requires a chiller whereas the other model is convection cooled and has a smaller footprint. All models have the following characteristics.

- An integrated measurement system combining visual measurements from linescan system, rail wear measurements from laser system, and track geometry measurements from laser and inertial systems

- Rail wheel interface measurements use data from this series equipment

- High quality sensors: (a) Colour/monochrome camera options,Pixel resolution up to 0.2 mm at low speeds (default set to 0.5mm/pixel upto 160 kmph), Line rate up to 200KHz, image resolution: 2048 x 2048 pixels (b) Inertial sensors of tactical grade (b) Laser: resolution 0.2mm; profile with 2048 points; spacing between samples at 160 kmph is 25 cm.

- Built-in LED lighting for all weather operations, 400,000 lux @ < 250mm distance, LED length 110-2150 mm long, IP67 or higher rated

- Operational Voltage: 24VDC, typical power consumption 6.5kW

- Expandable storage, 48Tb+ on-board storage

- Dedicated management software for remote control and cloud interface

- On-board real-time data analysis, offboard data re-processing available

The following video shows TrackVue Z making sensor measurements with vehicle speeds reaching 100 kmph. The lighting on rails, rail wide and pulsed lasers in blue are visible.