Fastenings & Joints Diagnostics

Background

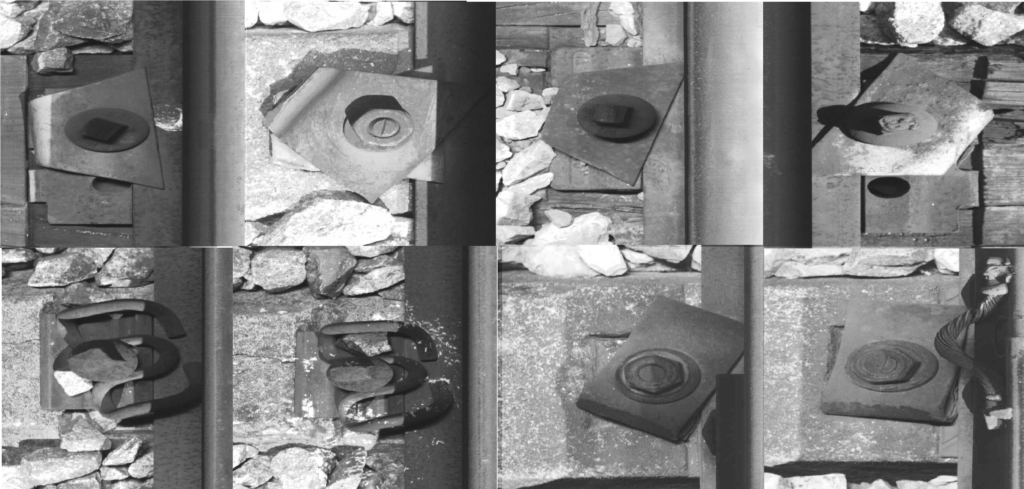

Rail to sleeper fastenings keep rail tightly coupled to the sleeper keeping uniform track gauge and other geometry parameters. A variety of fastenings exist as shown in Figure 1 below. Additional fastening systems include baseplate and spikes for wood sleepers, anchors for wood sleepers, and so on. Excessive and abnormally distributed track loads can force fastenings to rotate as they become loose or break-off over time. The detection of a single missing fastening may not indicate a major problem however a cluster of such defects may indicate a problem related to poor track geometry, unstable track bed or abnormal rolling stock loads which can be analysed through rail wheel interaction measurements.

It is therefore important to recognise fastening types and defects per sleeper and measure high risk zones containing either multiple missing fastenings on the same sleeper, or a number of successive sleepers with missing fastenings or missing fastenings next to a rail joint (all classified as high risk areas). TrackVue Z series is capable of detecting fastenings and reporting on missing fasteners.

It is therefore important to recognise fastening types and defects per sleeper and measure high risk zones containing either multiple missing fastenings on the same sleeper, or a number of successive sleepers with missing fastenings or missing fastenings next to a rail joint (all classified as high risk areas). TrackVue Z series is capable of detecting fastenings and joints and reporting on their condition and defects.

RV Diagnostics

Rail Vision uses linescan technology to detect rail-joint defects. Advanced image analytics makes a number of detections and measurements highlighted below.

| Joint measurements | |

|---|---|

| Fishplate type | Mitred, straight |

| Fishplate crack | Crack length, width, thickness, area, orientation, track position, severity |

| Rail gap | Rail separation in mm, track position |

| Damage at rail joint | Type (crushed joint, chipped, excessive separation), severity, track position |

| Fastening measurements | |

|---|---|

| Fastening type | Type (e.g. 4 bolt, 6 bolt, 8 bolt) |

| Fastening missing | Track position, type |

| Fastening loose | Track position, type |

| Baseplates | Type, track position, orientation |

| Baseplate defects | Type, location, associated measurements |

| Spikes in plates | Number per plate, pattern over sleepers, missing spikes, track position |

| Anchors | Position, missing anchors, anchor patterns, track position |

| Weld measurements | |

|---|---|

| Weld type | Type, position |

| Weld clamps | Track position |

| Weld defects | Defect type, position, measurements (e.g. weld fracture thickness), track position, severity |

The following picture shows the detection of missing fastenings with TrackVue Z series equipment.

The following picture shows the detection of rotated fastenings with TrackVue Z series equipment.

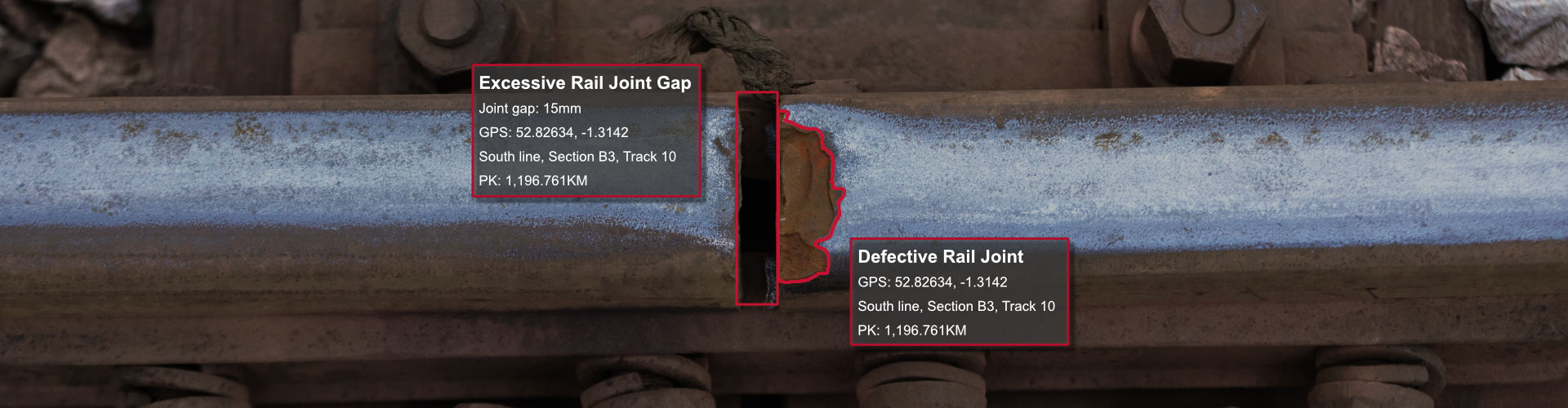

The following picture shows the detection of defective joints with TrackVue Z series equipment.

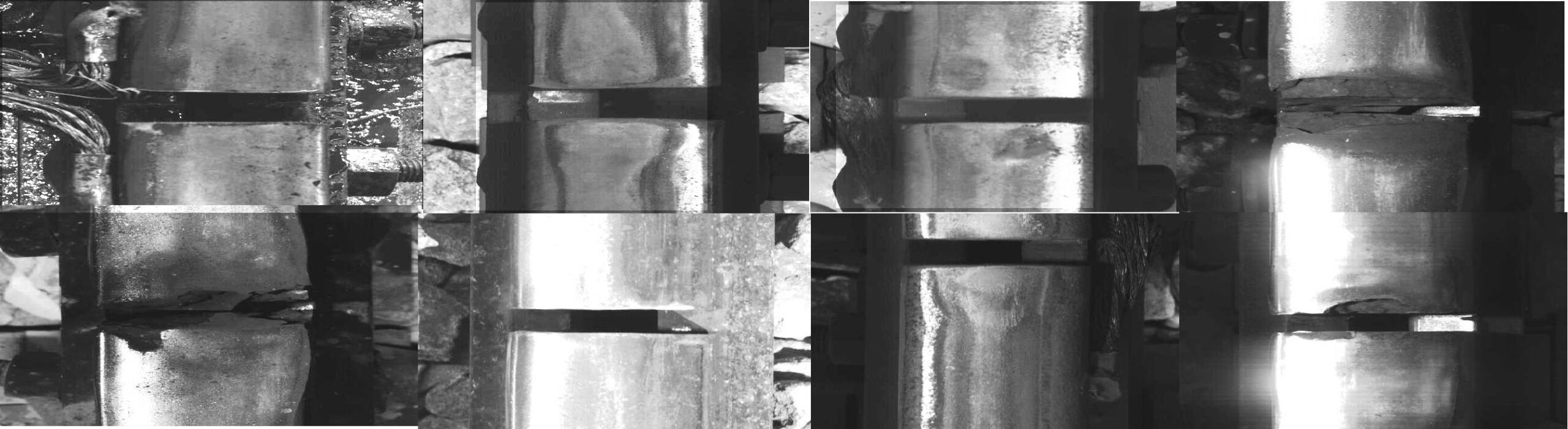

The following picture shows the detection of defective welds with TrackVue Z series equipment.

Similarly, railfishplates are also important to diagnose. A fishplate provides continuity between rails. Any mechanical changes to it, e.g. missing or loose bolts, as well visible joint defects including excessive joint gaps can increase the risk of further joint damage and derailment. In case of continuous welded railway, weld defects also need detection especially where weld fractures are imminent.

The following picture shows the detection of missing bolts on fishplate joints with TrackVue Z series equipment.

RV Advantage

- Very high resolution image analytics at 0.25mm/pixel for vehicle speeds up to 80 kmph and 0.5mm/pixel for speeds up to 160 kmph allowing us to detect new cracks developing on fishplates, and welds.

- Joints analysed both top and rail web views

- Innovative solution to detect loose bolts on fishplates in focussed track segments using plastic tails