Agritech Innovation

Rail Vision has been at the forefront of diversifying its activities into Agritech applications where a significant proportion of Machine Vision based Rail Technologies have direct application. Since 2013, Rail Vision has been actively working on collaborative projects with companies and academia to develop novel machine vision based sensor solutions for monitoring crops, increasing food productivity and coming up with new decision making tools for the farming community. Our focus remains on automated field condition crop monitoring and developing solutions that precision spray and reduce the application of fertilisers only to field areas that need it.

The following list shows some of our high profile R&D in this area, supported and funded by InnovateUK, a UK Government Funding Agency. The followed detailed projects have lasted between 2.5 to 3 years with the aim of developing prototypes that can be field tested. Rail Vision is currently in the process of considering diversification of its business into AgriTech area.

Agrivision Inspector- Development of a system for low cost, remotely managed, automated crop stress monitoring and detection in a protected environment using advanced imaging techniques and analytic

The proposed project was a collaboration between 3 organisations; Rail Vision Europe Ltd (RVL), a not for profit RTO, Rothamsted Research (RR) & a large company Certis UK Ltd (CUK) a UK subsidiary of Certis Europe BV. The project was led by RVL with a 68.03% stake in the project, RR 20.94%, CUK 11.03%. The project brought together a consortium with highly established crop specialists from RR and CUK, and electronic sensor, photonics, data processing and analystics systems specialism from RVL. The industrial research project was targeted at improving the efficiency of food production by engineering a novel, flexible multi sensor imaging system (HD, IR, flourescence) for mounting on a mobile platform (manual or robotic) for use initially in a protected crop environment.

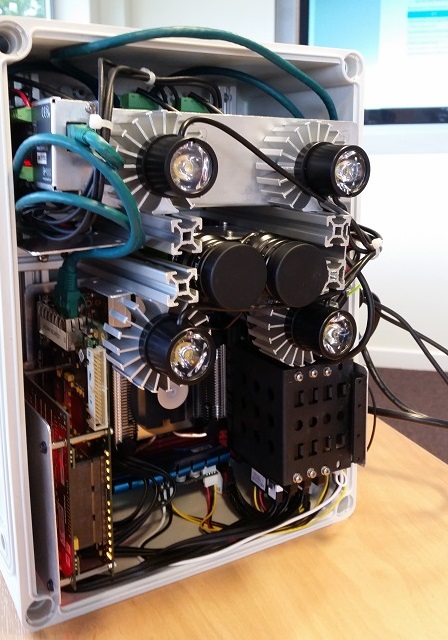

The imaging system developed worked with an advanced data analytics system to automatically detect and alert identified plant stresses and present the results and reports to end users in a traceable & recordable manner for automated crop monitoring & stress detection. The system was initially targeted at protected tomato crop stresses, but expected to be rapidly expanded to additional protected crops including cucumbers, fruits etc and eventually to an increasing range of crops. By facilitating increased crop monitoring, automated analysis and an earlier detection of crop stresses the project facilitated enhanced efficiency in use of resources by reducing the use of herbicides/pesticides, more targeted application of resources and increased yield for a given acreage. The project supported the application of increasing integrated pest management in the protected crop environment and minimising the potentially negative impacts associated with food production. Within just the tomato growing market in the UK, worth £175m p.a., a minimum of 10% losses costs growers £17.5m per annum. Improving yield in this sector by only 2% increases tomato yields by £3.5m p.a. The project engineered a solution for pest and disease control building on RR and other recent research into the use of intelligent multi-sensors for the detection of crop diseases. The picture on the left shows the actual device produced with multi-colour LED lights with a filter wheel, camera and processor plus storage, which can be mounted in glasshouses on a automated trolley for imaging tomato plants to determine their health status.

Tools and Technology for Predicting Tomato Glasshouse Production

UK sales of fresh tomatoes is valued at £625M with UK production providing £175M worth of these sales. Current estimations used to predict production are within 10% correct only 30% of the time. Over-estimation of production results in costly imports, whilst under-estimation incurs financial losses from the disposal of surplus fruit. There is considerable potential to reduce waste and financial losses, and increase the proportion of UK sales by improving the accuracy of weekly production forecasts. We developed a glasshouse-based imaging system TomVision and mathematical models PredictTomPro to more accurately predict production. This would deliver significant savings in import costs and waste. Our aim was to predict weekly harvests to 10% of actual, that will generate £30K/ha extra income p.a. (£6M UK). The anticipated sales of TomVision and PredictTomPro was estimated worth £1.3M/£11.7M (UK/EU). UK glasshouse cultivation of crops is technology-driven with highly intensive year round production. From a total of ~400 ha of glasshouse, 83k tonnes of tomatoes, 21k tonnes of peppers and 63k tonnes of cucumbers worth a total of £165M (farm gate) is produced. UK-grown tomato production is worth £175M (supermarket retail), with total UK sales worth £625M. Not all tomatoes produced reach the market with 7% going to landfill (£800K) and 11% to non-supermarket sales.

There is, therefore, a significant potential to increase the proportion of UK sales through reducing these losses which occur due to poor production prediction. This project will develop new innovative opportunities to improve the economic and environmental sustainability of this sector. Thanet Earth (TE), a partner in this bid for Agri-Tech Catalyst funding, supplies 10% of the UK’s glasshouse tomato production, and 10% of pepper and 8% of cucumber production. The consortium has expertise in agronomy and husbandry, crop physiology/nutrition, engineering, modelling and software development and a strong track record of delivering and exploiting results of publicly-funded R&D.

The proposed scientific and technological innovations have not been implemented by others in glasshouse production and represents leading edge applied science and engineering. The consortium will: 1) develop TomVision, an imaging system to count fruit and determine their ripeness and 2) refine mathematical models to predict production based on the image data generated and future weather conditions (PredictTomPro). These two activities will provide an assessment of TomVision and PredictTomPro to quantify the potential to deliver a greater efficiency in the use of resources, improved productivity from waste reduction and improved grower margins from more accurate production forecasts. We anticipate UK revenue gains of £6M p. a. (£30K/ha) farm gate value by adoption of the outputs and further income to project partners by sales of TomVision and PredictTomPro (£1.3M / £11.7M UK/EU total sales for tomato production). The route to market will be via roll-out to other UK tomato growers and overseas partners in the first instance, then to other UK, EU and worldwide producers of high-value horticultural crops where improved farming precision is required to advance sustainable intensification and deliver economic impact. The proposed project meets all the requirements of duration, project size, business involvement and RTO lead and funding balance for an Agri-Tech Catalyst Early Stage Award. RELEVANCE TO SCOPE: Overall TomVision and PredictTomPro fits squarely with the Agri-Tech Catalyst scope of bringing engineering solutions to primary crop production and loss mitigation using imaging and novel technologies.

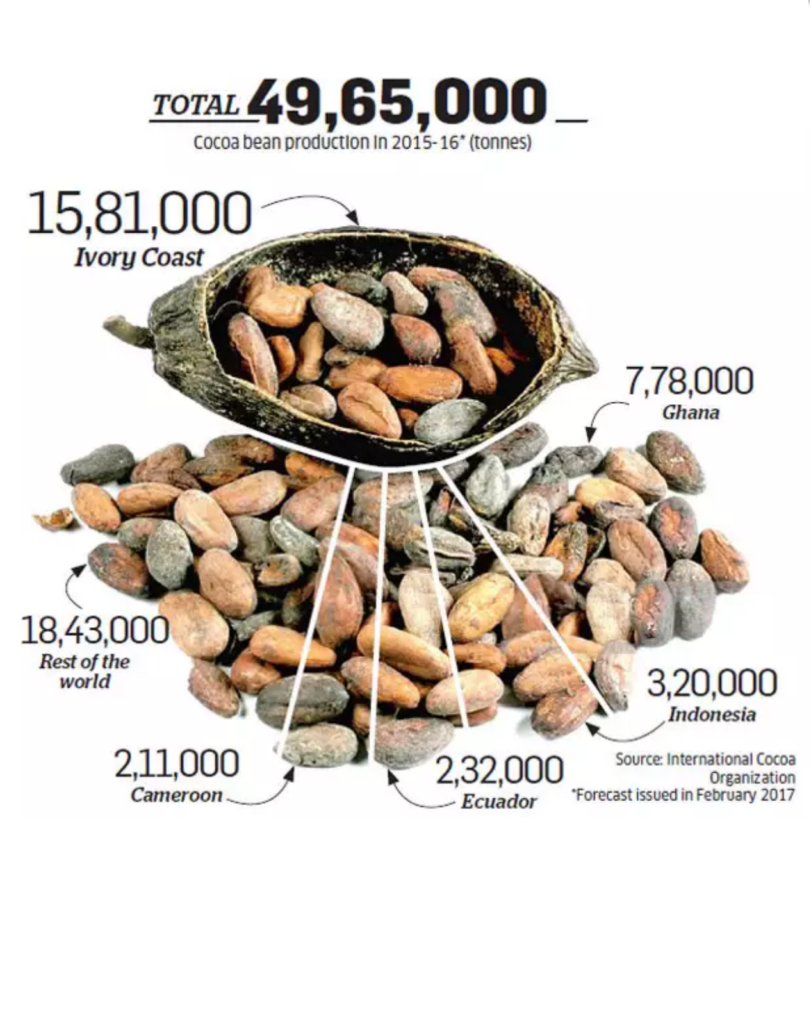

Development of aerial risk inspection, evaluation and surveying (ARIES) platform for cocoa plantations

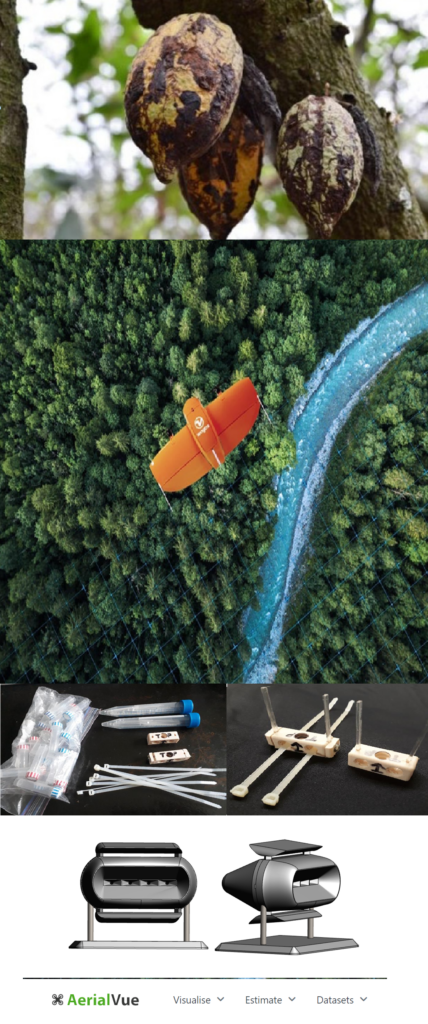

In response to the growing problem of losses associated with the CSSV disease in the West Africa due to unavailability of the localised information per hectare of the cocoa plantation which is key for the earliest possible remedial steps , this project is aimed at developing a platform technology (ARIES) based on mathematical models and software tools for satellite & drone imagery data analytics to determine the already CSSV infected areas & at high risk of being infected. The principle innovation lies in developing a platform which will provides cocoa plat condition & diagnostic data at a localised level for individual plantations. ARIES will be the first platform which will measure the probability of a localised area in plantation of already having the disease or developing it in the future through statistical measurements on plant density, diversity, growth, canopy cover, visual appearance & other factors. Project brings together Ghana & UK based consortium with diversed technical & commercial capabilities for successful development in line with our multiple customer types including regional organisations in Ghana (COCOBOD etc), agrochemical companies & cocoa processors who are in need of solutions such as ARIES for asset management, future demand planning, disease control management & acquiring targeted data for bespoke marketing.

Cocoa yield per hectare in West-Africa is on a continuous decline due to high incidence of pests and diseases, the old age of cocoa farms and lack of soil nutrients. Prevalence of cocoa swollen shoot virus disease (CSSV) is believed to be one of the major threats to the Africa’s (especially in Ghana) cocoa industry. Within last 10Yrs, >300,000ha of cocoa farm have been infected by CSSV, resulting in insecurity of the cocoa production in future and affecting all the stakeholders including farmers suffering from lower incomes, cocoa processing companies risking the reduced availability for chocolate production, cocoa distributors not having access to abundant cocoa & the regional organizations striving for the sustainable cocoa production. Since pesticides or other controls cannot be applied on all of the 1.9million ha of cocoa plantation in Ghana, therefore the definition of risk zones and risk levels in these is of great importance for managing CSSV effectively. Therefore the provision of the localized health information of the cocoa plantation for the individual hectare is key to implement targeted control measures via pesticides or cutting down for replanting. State of the art solution fail to provide early detection tools & solutions to restrict of the disease spread and the overall integrated approaches to combat the losses through CSSV.

Through this 36 months industrial research project, we Rail Vision Ltd (UK) in collaboration with Rothamsted Research (UK), Cirtus Europe Ltd (UK) & Positive Agro (Ghana, Africa) aim to develop a platform ‘ARIES’ which for the first time will be able to predict the exact location, current infectious status, future risk of being affected by CSSV of the cocoa trees and data on plantation condition to mitigate the risk by incorporating the key factors of canopy cover, plant diversity, height, chlorophyll level and tree density. The outputs of our platform will enable the targeted control of the CSSV through mitigation measures. The aim of the project is to provide detailed GIS information on these CSSV risk zones and combine it with GIS data of existing CSSV sites and areas where some control has been applied (pesticides or cutting down of trees). The developed system will modify this information over time with newer data, and provide tools to filter data, generate reports and compare information over a period of time to see the level of risk. The users of the developed system will be able to further retrieve localised image data for high risk areas. Key project activities include

.