Catenary Measurements

Background

Catenary wires need regular inspection to ensure that the contact wire is in correct position, within acceptable sag, in good condition based on its thickness, and follows the design geometry. Surrounding areas that deliver power to it including overhead masts also need regular checks to make sure that components are not damaged or overheating. Certain measurements in very cold or hot weather need to ensure that contact wire interface continues to perform within acceptable limits, and any deviations and power surges do not impact on the health of the catenary system. Three main types of measurements are important: overhead camera and laser measurements on contact wire; electrical discharge and thermal measurements at pantograph interface, and defects at overhead poles or areas which mechanically support contact wires.

Overhead measurements

Overhead measurements focus on the estimation of wire position with respect to rail and track, its condition, and its clearance from any surrounding vegetation. Abnormal pantograph-wire interface causes damage to both and reduces their expected life. High resolution imagery combined with laser measurement is used to determine wire stagger, height and thickness. Colour imaging of surrounding areas determines the proximity of vegetation to catenary lines. Each measurement is position indexed with track location, vehicle speed, track properties (e.g. curvature) and inertial data.

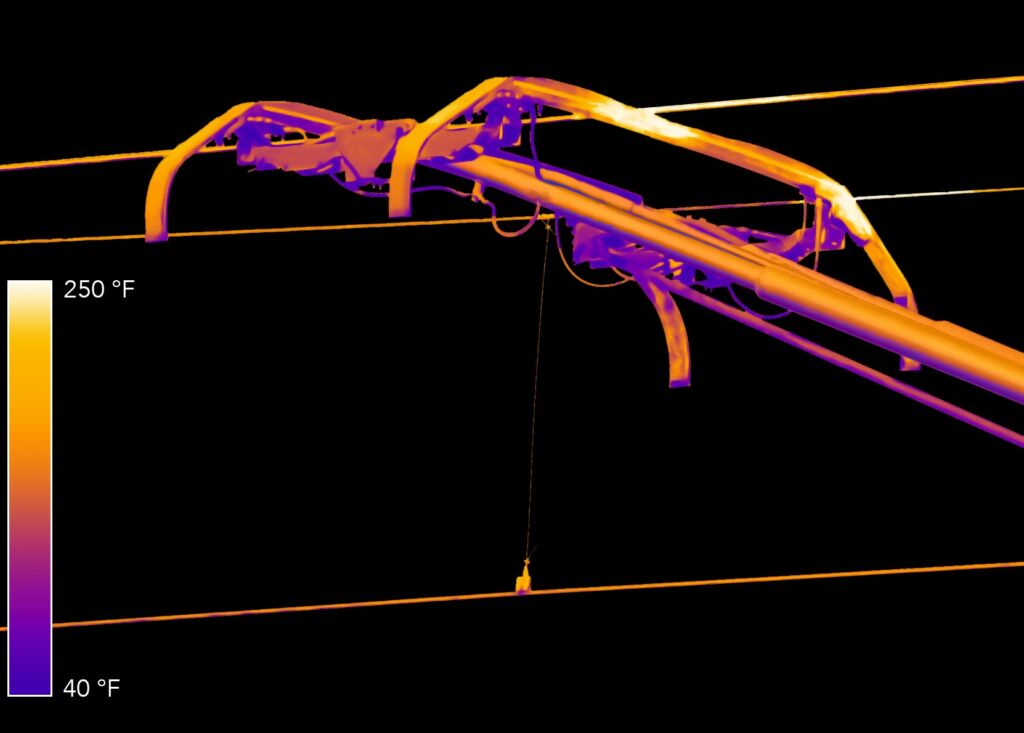

Electrical discharge, thermal measurements

A thermal imaging system tracks the pantograph/catenary wire interface as shown in Figure 26. The stress on the wires and pantograph pads is measured by evaluating their temperatures on a running train. The system can image temperatures between [0, 1000C]. Temperature gradient is measured to understand the dissipation of heat by various components over time. Electrical arcing at the interface is also detected and reported with location data.

Pole defects

Catenary wires are supported by a network of electrical poles positioned along the track. A series of electrical fixings and components hold catenary and contact wires with required tensioning. Over time, these electrical components and/or fixings may fail (e.g. insulators, joints) causing loose/broken catenary wires and loss of current. V Series equipment is designed to automatically detect trackside masts and take high quality colour digital photographs of components on these masts and fixings to determine through imaging analytics if there is a maintenance issue. Digital imaging data is further evaluated to identify any broken, missing or detached components. The output of such analysis is indexed with track location and a unique identifier for the mast.

RV Diagnostics

Our catenary measurement system uses V series equipment that is mounted on top of the vehicle, ideally on locomotives close to the pantograph position (5-8 meters away). The system uses a range of colour areascan cameras, linescan cameras, lasers and inertial systems to perform real-time data acquisition and analytics. Dedicated LED lighting is used to ensure that measurements can be made at night time. The following table shows the measurements our system makes. All measurements are indexed by track location (chainage) and GPS and results are available through RV Cloud web portal. The following measurements are made.

| Catenary Wire Measurements | |

|---|---|

| Classification | Type, Loaded/Unloaded |

| Wire Height | Height above rail level in mm with track location |

| Temperature | Temperature in Celsius, track location |

| Wire Stagger | Stagger in mm |

| Wire thickness | Thickness in mm |

| Gradient | Gradient profile in mm |

| Catenary Mast Measurements | |

|---|---|

| Type | Type and location |

| Transformers | Condition, track location |

| Hot spot defects | Thermal defects associated with wires, contacts, insulators, contacts |

| Visual surface defects | Broken & missing components, surface condition (rust and snow) |

The main challenges for monitoring catenary wires includes having rugged and robust equipment that can be mounted on the top of the vehicle, sensors and data management capable of performing a sample every 0.5 meter along the direction of travel, ability to work in all weather conditions and at night time and easy maintenance given that accessing equipment at heights is not easily possible. TrackVue V series equipment provides a low profile, adequate clearance rugged system for this purpose. It does not take any space within the cabin area and performs real-time data analytics. Defect images and laser measurements are recorded and transferred wirelessly to cloud for maintenance actions. Our inspections are guided towards predictive maintenance, and post-processing analytics driven towards changes between successive runs to identify deterioration and understand root cause behind it.

The thermal data analytics measures wire and pantograph contact temperatures. The temperatures are related to electrical flow and the amount of friction between the pantograph and the contact wire. The heat dissemination is affected in extreme temperatures which may cause sudden breaks. Our thermal camera systems can be configured based on user needs, i.e. temperature range, sampling frequency, and parameters of measurements required. In the simplest case, hot spot detection above set thresholds are flagged. In other cases, heat spread over a region may be analysed.

Overhead masts provide electric power and mechanical attachments to hold catenary system. These are also used to tighten the wires to remove sag. Our systems use high resolution colour imaging to photograph these poles to get details of wire joints, insulator pods, fastenings, junction boxes, etc. which can be analysed semi or fully automatically to recognise any damage. Thermal imaging coupled solutions can identify excessive thermal discharge at joints.

RV Advantage

There are a number of advantages of using RV V Series equipment for catenary measurements including:

- Measurements are made at full line speeds of up to 160 kmph; high speeds are possible

- Remote automated operation of measurement equipment

- Comprehensive measurements from the same unit